With ever-changing consumer demands, supply chain instability and increasing costs, the food and beverage industry is undergoing a spate of changes.

Both small suppliers, looking to lower production costs, and major producers, targeting even higher production volumes, are in search of solutions that can help them overcome the looming challenges.

3D printing is one of the technologies food and beverage companies integrate into their product development departments and production lines to optimise processes and decrease costs.

To help you better understand the state of 3D printing in the food and beverage industry, we explore application areas that can benefit the most from the technology and highlight some of the examples of 3D printing in action.

How do food and beverage companies use 3D printing today?

Faster packaging development

In the food and beverage industry, packaging serves as the interface between a brand and the consumer. Fundamentally, a good package design attracts the consumer’s attention and impacts the buying decision.

However, developing packaging designs typically involves multiple design iterations that can be costly and time-consuming. Food and beverage brands turn to 3D printing to speed up the packaging development process through faster and more economical production of design variations.

This is possible because 3D printing doesn’t require moulds or other tools for production, only a design file that is sent to a 3D printer and manufactured within several hours.

Furthermore, compared with conventional methods, 3D printing can create prototypes with the finished product’s features and in a variety of colours and materials. This enables food and beverage companies to test the final product look and feel, further enhancing design reviews.

For example, Thermos, a manufacturer of insulated food and beverage containers, has been using 3D printing for packaging prototypes since 2006. Switching from outsourcing prototyping jobs to in-house 3D printing reduced the lead time for a prototype from five days to several hours.

The company states that 3D printing allowed them to optimise the fit of the cap stopper and pouring performance of their best-selling Thermos mugs.

3D-printed spare parts for food and beverage factories

Food and beverage companies can increase line uptime by using 3D printing for spare parts production.

The technology helps to ensure that certain spare parts are made available faster, helping to avoid unplanned downtime.

Let’s take beverage filling plants for example. Such plants thrive on speed, with production rates ranging between 40,000 and 80,000 bottles or cans per hour. So, if a plant is shut down, its profitability quickly decreases.

In the worst-case scenario, finding the issue, requesting a spare part, shipping and installing it, can take a few days. Depending on the size and output of the entire filling line, an hour of lost production may cost anywhere from $4,000 to $30,000.

3D printing enables on-demand spare parts manufacturing that helps to reduce costly downtime. Reducing unplanned downtime, in turn, helps manufacturers to defer costly investment in new assets and increase productivity.

Cheaper ergonomic tools

A 3D-printed tool for a Heineken plant in Spain [Image credit: Ultimaker]

In-house 3D printing makes it possible to produce tools for food and beverage plants faster than with conventional processes.

Some of the tools suitable for 3D printing are:

Maintenance tools

Safety tools

(Dis)assembly tools

Ergonomic tools

Quality assurance tools

Spacer and alignment tools

Furthermore, as 3D printing offers design flexibility, tools can be designed ergonomically, providing greater ease-of-use for workers and improving accuracy when performing tasks.

6 examples of 3D printing in the food and beverage industry

1. 3D printing helps Pepsi to advance packaging design

[Image credit: Pepsi]

Global food and beverage brand, Pepsi, has used 3D printing to create a replica Black Panther mask for soda cans as a part of the promotional campaign for the movie.

Aiming to develop and produce 250 intricate masks as quickly as possible, Pepsi decided that creating moulds would be too expensive. Given its design flexibility and economic low-volume production benefits, 3D printing provided an ideal solution.

Through the partnership with the contract manufacturer, Protolabs, the team used material extrusion technology to create the initial prototypes of the masks. They added some modifications to ensure that the design worked with the picture on the can and that it would remain secure during shipping.

To create the final parts, the team opted for HP’s Multi Jet Fusion technology because of a high-quality surface finish and lower production costs.

In total, it took under six months to go from conceptualisation to a final product, all thanks to 3D printing technology. Both the Pepsi cans and their sleek 3D-printed masks helped gain a lot of attention for the movie, showcasing the power of 3D printing to help develop innovative packaging designs.

2. Redesigning a part for a brewery plant

Kaspar Schulz’s new 3D-printed lautering blade cuts the early brewing stages in half, meaning more beer in less time. [Image credit: GE Additive]

In partnership with GE Additive, Kaspar Schulz identified a couple of parts that could benefit from a redesign. One of them is a component inside a Lauter Tun vessel which separates wort – the liquid extracted from the mashing of beer – from solids.

This part is called the racking arm and the team wanted to improve the filtration effect of the spent grain bed inside the vessel.

To achieve this goal, GE and Kaspar Schulz designed a thinner blade with internal channels, which loosens the spent grains and distributes water evenly throughout the bed during rotation. Kaspar Schulz’s Head of Research and Development, Jörg Binkert, believes this feature will improve both processing time and yield.

In general, the company sees the key benefits of using AM in the functional integration of parts, which helps to reduce the number of joints and seals. These opportunities, unlocked by the design flexibility of AM, will pave the way for incremental improvements in the brewing process.

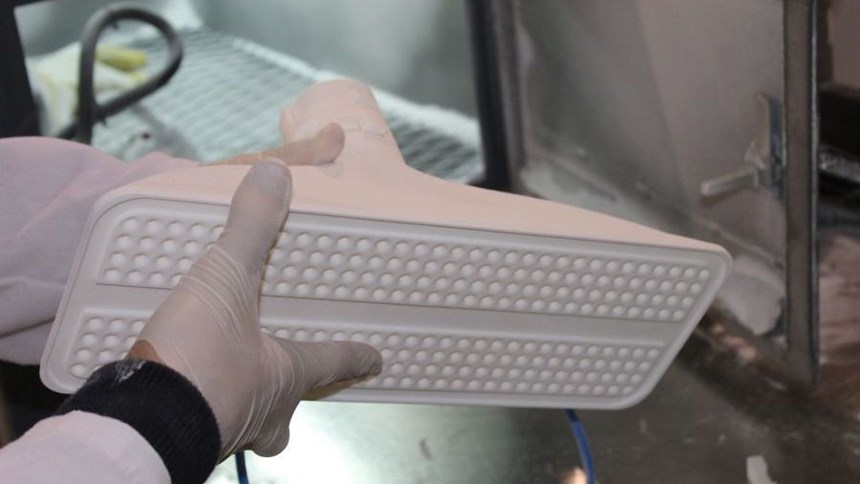

3. 3D-printed grippers for a food packaging line

Another application for 3D printing in the food and beverage industry is robotic grippers used on food processing lines.

Food processing lines often require custom solutions, and 3D printing offers a viable means of producing grippers customised for specific requirements of these lines.

Furthermore, 3D printing makes it possible to reduce the weight of a gripper, unlocking a range of benefits. For example, a lightweight gripper, with the same load capacity, supports faster movements and enables shorter cycle times – a key objective in the manufacturing world.

One company taking advantage of 3D-printed grippers is Icelandic food processing company, Marel. The organisation collaborated with the Danish Technological Institute on the development of nylon grippers integrated into robotic arms that grab meat, such as fillets, to lift it on and off the conveyor belt.

Marel uses 3D printing to create robotic grippers for food processing lines [Image credit: Marel]

Marel sees the critical benefit of 3D printing in its flexibility: the company can customise grippers for different customers without the added cost of milling tools. Additionally, Marel can order grippers to be 3D printed on demand, with a delivery time of just three days – which also helps the company to reduce storage costs and increase agility.

4. Innovating a robotic gripper design

[Image credit: Anubis 3D]

The Anubis 3D team applied topology optimisation software to create a design that both meets the requirements and is suitable for 3D printing. In the optimisation process, the software algorithms analysed stresses and strains on the structure and adjusted the geometry of a part for strength and lighter weight.

Then, to further increase the grip of the tool, the team created a new design, with profiled holes and channels, that could not have been manufactured conventionally.

3D-printed in nylon, using powder-based 3D printing technology from EOS, the resulting part turned out better than expected. The new gripper provides four times the gripping force of legacy vacuum grippers, uses less air and has greater picking power.

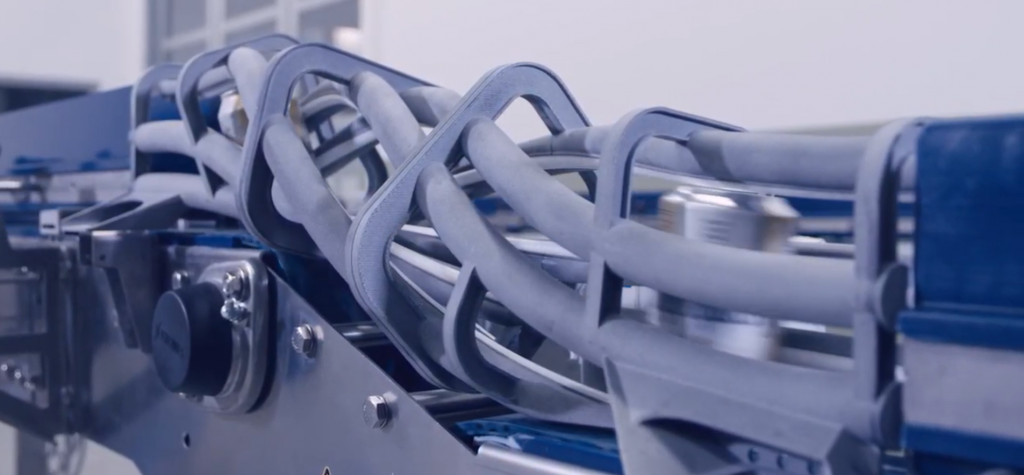

5. Krones develops a 3D-printed can twister

[Image credit: Krones]

One such project involved a can twister, 3D printed using a thermoplastic material. In a brewery, for instance, a can twister vertically inverts beer cans by 180 degrees after these have been filled and seamed so that these can then be pasteurised standing upside down.

During the development of the 3D-printed component, many different factors need to be analysed, including the optimal motion sequence of the cans as they are inverted.

The development team needed several attempts to create a design that met all the requirements. But thanks to the advantages offered by AM, the path from design to actual implementation was short.

In addition to faster development, 3D printing creates can twisters with a high level of repeatability – which was a challenge with a manual machining process that would result in deviations in part geometry.

Krones has already successfully tested the can twister in-house, with up to 150,000 cans per hour, and now expects to integrate the component into each of its new canning lines.

6. Heineken optimises its manufacturing line with 3D printing

After around two years of using 3D printing, Heineken identified multiple applications that helped improve the safety and productivity of its operations.

With the help of Ultimaker’s extrusion 3D printing technology, engineers at the Heineken brewery plant in Spain quickly learned that they could save a lot of time and money by 3D printing custom optimised parts and tools for its production line.

For example, a metal can pusher, used to reject and direct bottles, would cost substantially more and have a longer lead time than a redesigned plastic 3D-printed alternative.

Similarly, the company started 3D printing a stopper tool, which loosens and tightens the columns of guiding wheels that apply bottle labels.

3D printing the tool resulted in dramatic cost savings of 70 per cent and faster delivery time (from three days to one) compared to the previous method of CNC machining. Other simpler tools, such as a toroidal rubber cutter, can be 3D printed in less than an hour.

Overall, the brewery saw several improvements to its production after the adoption of AM in-house. On average, Heineken said it experienced 80 per cent faster delivery times and 80 per cent lower costs for parts.

3D printing in the food and beverage industry: The driver of efficiency

The food and beverage industry is grappling with many challenges, and 3D printing provides an efficient solution to some of them. It helps food and beverage companies develop better packaging, stay agile with on-demand 3D printing of spare parts and tooling, and improve operations with advanced components.

Going forward, we’ll see more food and beverage companies investigating the technology to drive efficiency and meet the challenges of an uncertain future head-on.